Bake-Out

Building a

Image from pixelliebe/ iStock/Getty Images Plus via Getty Images

Revisiting the Basics of an Effective Chemical Remediation Tool

By Michael Pinto & Jacob S. Kooistra

Many people in the environmental industry have heard of the terms “sick building syndrome” and “indoor air quality” (IAQ), but substantially fewer understand the concept of “building bake-out”. This technique is now well established in the environmental field and yet still has, in some respects, a checkered history of acceptance and or derision among IAQ control professionals.

In its essence, a building bake-out is relatively simple. The term was coined to describe a process where the inside temperature of a building is intentionally elevated temporarily to speed the curing of paints, mastics, or other finishes. A building bake-out also can be used to accelerate the off-gassing of residual volatile organic compounds (VOCs) from orient-strand board (OSB), carpet, office furniture, particleboard, and various other manufactured components of the structure or its contents.

A Loose Approach

Since there are no widely accepted formal procedure or standards for a building bake-out, the staggering range of options available to the homeowner or facilities manager can be overwhelming. Options have been presented at conferences, as well as in promotional and scholarly literature, where external heat sources were employed in addition to the existing HVAC system. This suggested supplemental heat has ranged from electric space heaters to truck-sized systems requiring the use of portable generators. Obviously, such additions come with varying degrees of cost and complexity. One of the complicating drawbacks of using an outside heat source for the building bake-out is the fact that the temperatures generated by such auxiliary equipment often requires more active ventilation at the same time as heating.

Regardless of the technique employed, the most important issue is “Does building bake-out work to effectively reduce VOCs levels in homes and commercial buildings?” As with so many techniques that have come to be used with regularity in the IAQ field, there is limited scholarly data available from academically rigorous, scientifically controlled, studies about the effectiveness of the technique. Such studies would carefully compare the effectiveness of building bake-out to other remediation approaches — or even in comparison to doing nothing. This lack of hard data has led many IAQ investigators to discount building bake-out as an unproven technique, or, at best, a psychological salve for the unsuspecting or gullible occupants.

Balancing Risks and Benefits

Despite its derision in some quarters, there is a long history of anecdotal data that building bake-outs have solved real problems. Additionally, there is scant evidence even anecdotally of a mild building bake-out, such as the approach recommended by Wonder Makers, doing harm. Since a building bake-out can be is relatively inexpensive and an easy to implement option with little downside risk, our organization recommends it frequently. It is especially appropriate as an initial unintrusive corrective action when we suspect that chemical off-gassing may be among the factors in an IAQ problem situation.

It is also critical to remember that a building bake-out is not a substitute for effective source control. In fact, using the technique while removable sources of VOCs like portable fuel containers, open paint cans or alcohol decanters, are in the building can actually increase the contaminant level rather than lead to a substantive reduction. Therefore, an objective site inspection with the focus on removing the recovery sources of chemical off gassing is an important part of the entire building bake-out process.

Another step that is often neglected as part of a building bake-out solution is the inspection of the HVAC system. The question as to whether the existing equipment can elevate the temperature to an appropriate level and distribute that heated air to all areas of the structure should be determined before a bake-out is undertaken rather than finding out in the middle of the process that the existing mechanical systems are not robust enough to do the job. A thorough inspection also helps determine if additional local exhaust may be necessary at the end of the process in order to ensure that any liberated VOCs are flushed out rather than being reabsorbed. Finally, a thorough inspection is critical in order to identify any IAQ concerns which can be made worse by a bake-out attempt. The most common mistake in this category is failing to identify mold infestation in the HVAC ducts. Such circumstances can lead to fungal contamination in the building being significantly exacerbated by a bake-out attempt. Therefore, investigating the site and occupant symptoms in detail before recommending bake-out as a corrective remedy is a must.

The Wonder Makers Approach To Building Bake-Outs

Once the determination has been made to use a building bake-out process to attempt to alleviate an IAQ issue, the building owner and/or consultant needs to develop a specific plan. Making vague statements like, "we will turn up heat for a few hours and then open the windows" may capture the essence of the project but certainly does not provide any real direction that would offer the best chance of resolving the problem without creating additional difficulties.

The detailed process utilized by Wonder Makers is based on building bake-outs used in numerous situations over the past 21 years. In our experience, the theory of adding supplemental heat to that which can be supplied by the building’s existing HVAC system to increase the intensity of a bake-out process has not provided the value worth the extra expense and "hassle". While this theory suggests that such additional efforts may lead to a more complete bake-out or a faster heating cycle, our real-world experience has produced just as successful of results with less cost through a detailed and disciplined process using the existing mechanical systems. Obviously, this process has the substantial advantage of not requiring additional supplemental equipment or supplies other than what most homeowners or property managers have readily available. While the bake-out takes approximately 32 hours to complete, the actual active participation time is much lower. The entire process can be easily implemented by homeowners or maintenance or custodial personnel with only a few simple occasional interactions.

Understanding The Details Of The Building Bake-Out Process

For a bake-out to be successful a number of controlled steps need to be implemented. It is important to understand each of the steps and prepare the building for each one of them before the entire process starts. Such preplanning helps to make sure that any volatile organic compounds which are released during the "baking" portion of the process are quickly removed from the structure, rather than being allowed to reabsorb into other porous materials.

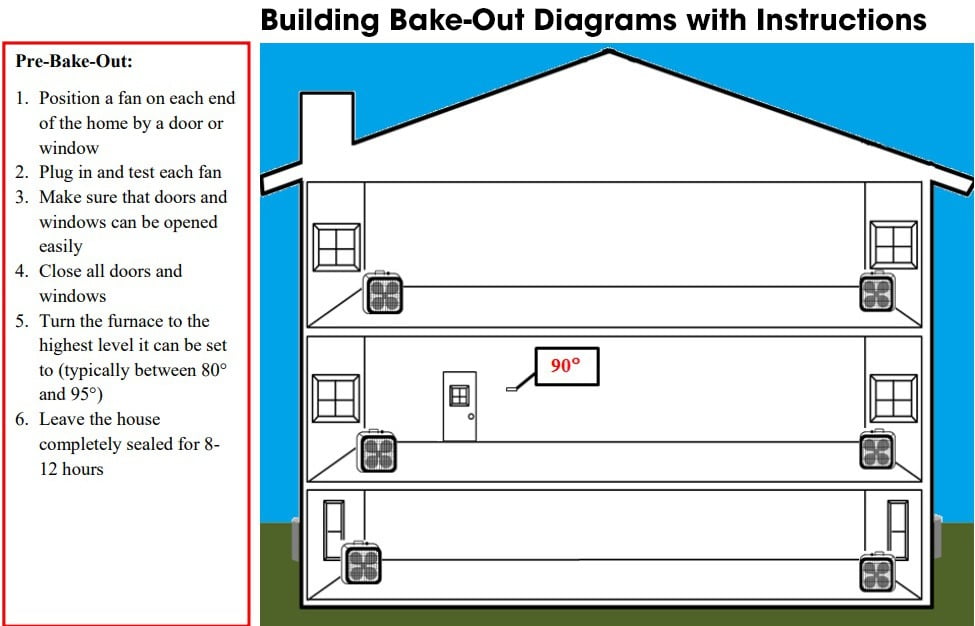

First, the exterior doors and windows are closed and the heat inside the building is raised to its highest attainable temperature; which for most residential systems will be in the 85-95° Fahrenheit (F) range. It is important to monitor the temperature over the first 30 to 60 minutes to make sure that temperatures in the house do not exceed 95°F. Anything above that upper limit puts electronics and other contents at risk. For example, many decorative candles in homes will melt between 100 and 140°F. Even at the low end of 100° F, candles can melt in under two hours.

Once the space is set up and checks to ensure that the temperatures will not get too high have been completed, the building is kept sealed and allowed to “bake” for 16-24 hours. During this bake-out period, it is often uncomfortably warm in the space for other tasks to be completed, even leaving aside any off-gassing that is occurring and impacting the air quality. Because of this, appropriate respiratory protection may be needed during the periodic checks on the space. Such assessments can be done quickly and should minimize the potential for allowing cold outside air into the building. Even having to take those precautions such checks of the integrity of the structure are an important safety step to ensure that the heat beyond normal operating temperature does not damage contents or the structure.

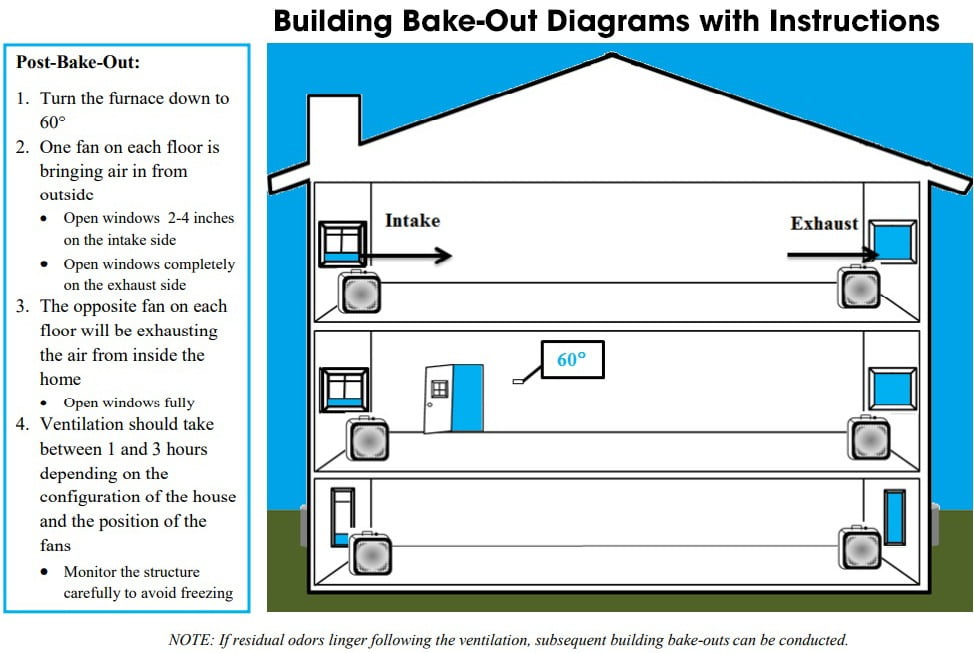

After the heating phase is completed, the building is unsealed and vented to the out-of-doors. This is done by directing the air, using box fans, floor fans used for drying carpet, or industrial size air movers. Switching on all kitchen and bathroom exhaust vents, as long as they are vented directly to the out-of-doors rather than into hidden areas of the building such as attics or crawlspaces, can also be helpful.

The air movers should be set up in such a way as to force the air to cycle out of each room directly to the out-of-doors. If the number of fans is limited, the air to be exhausted can be directed from individual rooms to a main hall, then out one end of the building. The building or space should be vented for approximately 8 hours or long enough for the air to be completely changed many times over in order to flush the intentionally rapidly released VOC’s out of the indoor space. The attached sketches illustrate some of these steps.

An Instructive Case Study

With such a background, and with a warning that building bake-outs should not be viewed as a cure-all, a case study of a Wonder Makers project may provide information necessary for IAQ professionals to feel more comfortable adding the bake-out procedure to their arsenal of possible remedies for building problems.

In this case, our organization responded to a complaint made by a teacher with an investigation of the newly built middle school. After occupying the building at the start of school two months before, the individual instructor was complaining of headaches, malaise, lethargy, irritated eyes, and upper respiratory distress. The investigation included a detailed site inspection and occupant interviews.

The affected individual told the investigator that they were allergic to many items, such as petroleum products, new car scents, and so forth. The teacher also indicated that a number of other individuals who shared the same room on a regular basis were also experiencing similar symptoms. This same individual also reported that they felt much better in the other rooms in the same facility with different flooring materials.

The visual inspection of the building revealed that the only difference between the room that was causing issues and the other rooms where the issue was not present was that the problem room had carpet on the floor and the other areas were tiled.

Examination of the MSDS for the carpet identified one of the substances used in the manufacturing of the carpet to be petroleum distillates, one of the specific items that the individual who reported the problems had previously identified as a known allergen.

We recommended to the building representative that the bake-out process be initiated over the upcoming weekend. We explained to the school administrator how to conduct the bake-out and venting of the building.

Following the bake-out process, the sensitized individual was surprised by their lack of symptoms when in the building. The other affected individuals also demonstrated alleviated symptoms, as well. Continuing follow-up over the next 30 days confirmed that the bake-out was a success. The school’s administration stated that no more complaints had been brought to their attention.

A Few More Tips

In the case described above, a single bake-out process did the trick. However, with over 20 years of experience we have learned that some situations require multiple cycles of the bake-out to remove all of the offending contaminants/odors. The key in deciding whether additional cycles will be helpful is whether any relief is gained from one, or subsequent, applications of the bake-out technique. Several of our projects have seen the bake-out process repeated three times, with one specific instance where it took four complete cycles to alleviate the problem.

While the perceptions of the occupants are going to be the measuring stick for when a building bake-out should be used, and if it is successful, there are more objective measures to determine before and after concentrations of contaminants. The traditional approach to the VOC sampling is a summa canister (a stainless-steel container that has had the internal surfaces specially treated to make them chemically inert so that the captured air is not altered before it is tested by the lab), but simpler techniques are now available. The use of specially designed sorbent tubes has revolutionized the VOC sampling process. As a result, numerous labs now specialize in analyzing VOC samples and identifying minute amounts of contaminants.

What It All Means

With one organization recommending and evaluating the bake-out process for over hundreds of clients over 21 years, the technique can no longer be considered controversial. For numerous types of chemical exposures and building products/contents off-gassing situations a building bake-out is a win-win-win situation for the building owner, the occupants, and the IAQ professional. With these more detailed recommendations on how impacted individuals can carefully apply the building bake-out procedure it is clear that the concept has moved from a perception of potential quackery to a legitimate response to VOC contaminants.

Michael A. Pinto currently serves as Chief Executive Officer of Wonder Makers Environmental, Inc. He has more than 30 years of safety and environmental experience from jobs in the private sector, the non-profit arena, and regulatory agencies. Michael is the author of five books, including Fungal Contamination: A Comprehensive Guide for Remediation, over 150 published articles, and 18 commercial training programs. He can be reached at map@wondermakers.com.

Jacob S. Kooistra is an Environmental Specialist with Wonder Makers Environmental, Inc. For 10 years, Jacob has worked in the property restoration industry, specializing in mold remediation and caring for sensitized individuals. In his current position, Mr. Kooistra assists building owners and occupants when they face indoor air challenges related to mold, lead, asbestos, and chemicals.