Containment Strategies

Photos credit: Rachel Adams

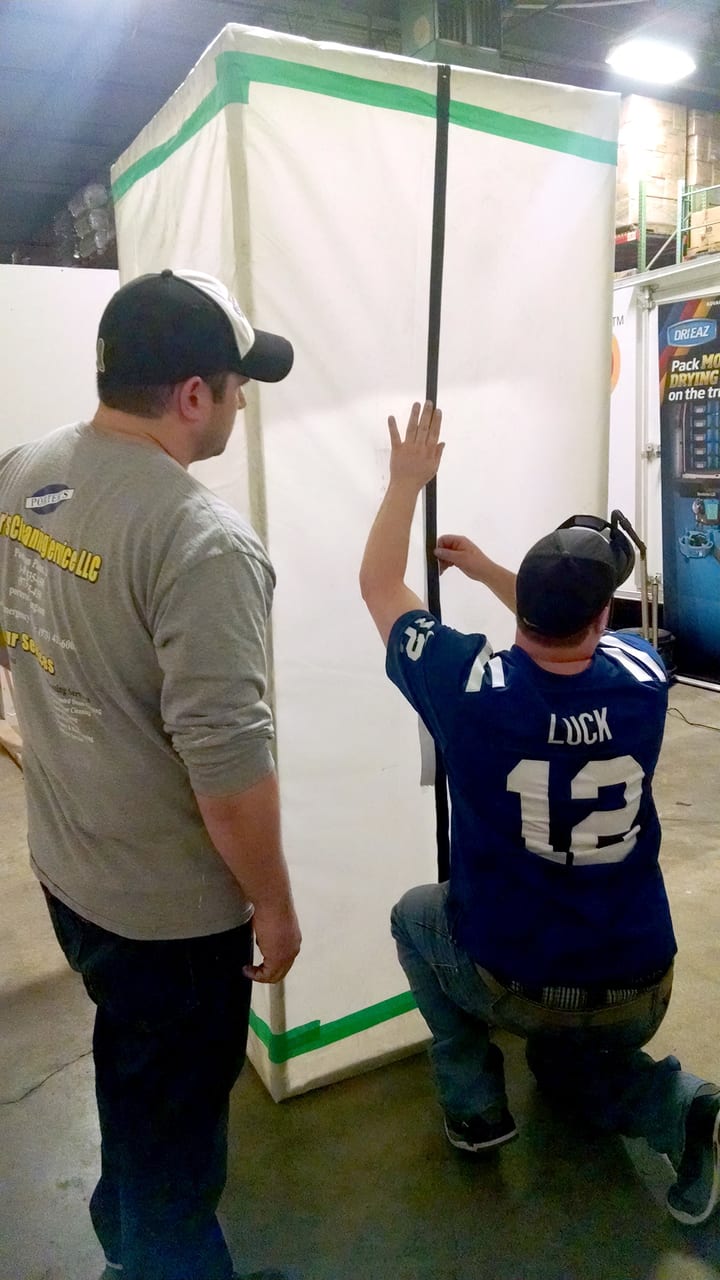

What Does Your Containment Say About Your Company?

By Rachel Adams

Building containment is typically not a specialized skill that many contractors have developed. While, technically, there is no wrong way to build containment, it needs to be constructed so that it accomplishes the main goal, to prevent cross contamination! But many contractors take short cuts, and may not have the right materials or the skillset/knowledge to build quality, professional containments. At the end of the day, the containment built is a direct reflection of the professionalism of the contractor that built it. If it looks like a third-grader built it, what will the customer think about the quality of work being performed on the other side?

It is not just about taping some plastic over a door while moldy materials are being removed. Containments can serve different roles throughout the remediation process. They may serve as a barrier initially, to prevent contaminants from leaving the work zone. Once the remediation is completed, if there are remaining wet materials that require drying, it can serve as a drying chamber. Containments can be a courtesy for the customer to leave in place through reconstruction and serve as a dust barrier. The technician needs to think about the different purposes a containment may serve. Think big picture!

General Considerations

When designing and/or building containment for a specific project, there are many factors that need consideration. They can have a direct impact on how well the containment will serve the technician.

- Construction quality: How long does the containment need to be in place? If it is a large project, it may need to be in place for several weeks or even months. The contractor should construct it so that repairs are not needed every day (re-taping plastic). What type of building is the project in? Containment in a commercial building may have limitations placed on the contractor as to the types of materials allowed for use (e.g. hospital). There may also be space limitations in projects such as residential that also dictate the size and design of the containment.

- Functionality: The use of exit/decon chambers is needed on all projects and should be included in the design. How accessible is the containment to allow for proper entry, exit, adequate equipment and debris removal? The contractor also needs to address any safety concerns, which should always be their first priority.

- Cost: There are many materials used in containment building, but they should make sense from a cost perspective. After all, the goal is not only to reduce liability, but also to be paid! While a contractor won’t get rich from building containment, they should not lose money either.

Containment Types

There are three basic types of containment: Source, local and full. Source containment can be used to stabilize an affected area prior to containment construction or remediation. It is commonly used for small amounts of mold growth. It may be used alone when fungal growth is limited to small, visible, controllable areas where no hidden growth is anticipated. Local containment may be used to isolate a section of a room or area. They are intended for “moderate levels” of fungal growth, whether it is visible or suspected. After construction, negative air should be established. Full-scale containments are normally used when significant and/or extensive mold growth is present or suspected. Critical barriers and negative pressurization must be obtained to contain dust and spores.

Exit/Decontamination (Decon) Chambers

One of the most important components of a successful containment is the use of an exit/decon chamber. These chambers are attached to the main containment chamber, and serve as a transitionary space between the contained area and the unaffected areas. They also provide a space for the technician to don and doff their personal protective equipment (PPE) to prevent contaminants from being released from suits and gloves upon exit. Most importantly, these chambers serve as an airlock to prevent loss of established air pressures upon entry and exit. When a technician does not use an exit chamber, cross contamination of unaffected areas is highly likely.

Pressure Differentials

When working in contaminated spaces, a lower partial pressure differential is most commonly used. This prevents the contaminants from leaving the work area and impacting unaffected areas. When creating negative pressure, the airflow should flow across the work area, which will allow for the contaminants to be captured by the HEPA air filtration device. Not only will this decrease cleanup time; it will also serve as an engineering control to prevent spores from overloading the respiratory protection.

When creating negative pressure, the “Bioaerosols: Assessment and Control and the IICRC S520 Standard for Professional Mold Remediation” states a negative pressure of -5 to -7 Pascal should be maintained throughout the remediation project (Or -0.02 inches of water column). How does the contractor determine if adequate negative air has been achieved? One way is by visually looking at the plastic. If the plastic is being drawn into the containment, it shows that the area is under negative pressure. Smoke tubes can also be used, in which the contractor watches the direction the smoke is traveling. High pressure will always go to a lower pressure, so this method can also indicate if a lower pressure has been established.

But how much negative air has actually been created? The only true way to measure pressure differentials is by using a manometer. There are different gauges and monitors that can be used to measure pressure differentials. A Magnahelic gauge is an inexpensive way to monitor pressures, but does not provide the ability to generate real-time data remotely. Other meters such as the Omniguard not only allow for pressure readings to be collected at programmed intervals; they also log the readings into a memory, which is then printed out as a hard copy with all readings collected that are date and time stamped. Certain jobs such a hospitals and schools may require a meter that can provide this type of data.

Make-Up Air

Make-up air is important to prevent collapse of the containment. Without adequate make-up air, a vacuum is created within the containment and can result in damage or failure of the structure. Pleated pre-filters can be installed into the containment to allow filtered, make-up air into the containment. These filters can remove particulate that are one micron in size, which is smaller than mold spores, therefore eliminating the risk of bringing contaminated air into a contained area.

Industrial hygiene practices recommend a minimum of four air changes per hour (ACH) for containment ventilation and dilution. The definition of an air change is to exchange, process, filter or replace the total air volume (TAV) of a contained area. The amount of equipment required to achieve the recommended number of air changes is determined by the CFM the machine produces and the cubic feet (CF) of air within the containment that needs to be processed. In some specific projects, the number of recommended air changes may be much higher, such as in an ICU unit of a hospital.

When calculating the number of ACH a specific pierce of equipment can achieve, it is important to understand the AFDs CFM performance rating is not the actual CFM a unit delivers. The actual CFM is lower than the factory rating due to resistance in the filter elements, dirty filter elements (back pressure) and attached ductwork (static pressure). Some AFDs are rated by manufacturers without filters, which will also restrict the airflow once filters are installed and should be taken into consideration when making this determination.

Critical Barriers

These barriers consist of double 6-mil polyethylene sheeting that covers all access points that prevents make-up air from being drawn from it. The most common access points could include, but are not limited to, light switches, outlets, floor drains, HVAS diffusers and vents. These accesses are intended to be covered, and not used as a point of entry or exit, and remain in place for the duration of the project.

Final Points for Discussion

The approach often taken by contractors is the simple and quick method to set up containment. In reality, the design and construction of containment often takes far longer than the actual remediation. Containment is one of the highest liabilities that impacts the contractor, as well as the client, and should be given priority. The best way to become proficient at building containments is practice, practice, practice!

Rachel Adams has been involved in the water damage and environmental health industries for more than 27 years. She holds a Master Restorer designation from the IICRC and is a project director for J.S. Held. Adams was founder and president of Indoor Environmental Management, Inc. (IEM) in 1994, where she conducted inspections of residential and commercial buildings throughout the country. She served on the board of directors for the IICRC and was appointed to serve as the technical advisory committee chair for the development of the IICRC Applied Microbial Remediation Technician (AMRT). Adams serves on the committee to write and establish guidelines and updates for the S520, Standard and Reference Guide for Professional Mold Remediation, and currently teaches AMRT, WRT, ASD, HST, OSHA and other classes. She is an honorary board member for the Society of Cleaning and Restoration Technicians (SCRT), and an associate member of the American Conference of Governmental Industrial Hygienists (ACGIH) and the American Industrial Hygiene Association (AIHA).