Photos credit: Getty Images

Job Hazard Analysis –

The Proactive Method for Safety Management

By Barry Rice

The Job Hazard Analysis, or JHA, is a form that identifies tasks associated with a job, the hazards of those tasks, and the controls to eliminate or minimize those hazards. It has many other names — Job Safety Analysis, Site Safety Analysis, and Hazard Analysis to name a few. They all accomplish the same thing, which is to mitigate hazards and prevent injuries.

I know what you are thinking, “Another form to complete, just what I need.” Hear me out on this one. I have seen it work well at minimizing hazards and greatly increasing awareness.

Job Hazard Analysis = Hazard Mitigation and Injury Prevention

IS A JHA MANDATORY?

OSHA requires employers to provide a workplace free from recognized hazards. They also provide guidance on completing a hazard assessment and selection of PPE. (A JHA can accomplish these requirements, so basically, yes, OSHA requires a JHA. To further support that, my personal experience is that anytime OSHA shows up for a jobsite investigation, the inspectors have consistently asked for the JHA.

I wouldn’t recommend viewing this requirement as just another form that slows down a job and doesn’t contribute value. View it as a proactive preventative measure. Think about the ramifications of an injury — injury impact to the employee, a worker’s comp claim, time away from work, finding a person to fill in, impact to the client if OSHA investigates, etc. The time taken to complete a JHA and explain it to site workers suddenly appears well worth it.

Finally, I get asked many times a year if a JHA needs created for every job. My response is that there is only one way to account for the variety of hazards at each jobsite; that is to create a JHA for each job.

THE JHA DOCUMENT

An online search will reveal many JHA templates. I can’t say that one is any better than the other. Go back to the basics and assure you have columns for the “Task”. “Hazards”, and “Controls”, as well as section for identifying PPE and a worker’s signature. Simpler can be better for most restoration work.

I recommend considering how your restoration firm could utilize electronic forms for completion and signing JHA’s on the jobsite via a laptop, tablet, or phone (this could speed up the process, as well).

Noteworthy in the world of JHA forms is the Site Safety Assessment Guide and Form located at www.ssaform.com. This was developed by a group of Canadian fire and flood restoration professionals and is geared specifically for the Restoration Industry. There is a comprehensive explanation and instructions on the webpage.

THE BASIC JHA PROCESS

The JHA process starts prior to work beginning. Typically a supervisor, project manager, or safety manager discusses the job steps with someone most familiar with work to be done. The job is broken down into basic steps. For instance, for a simple water extraction and drying job, the tasks could be:

- Mobilize equipment to job and setup in building

- Move furniture or other items

- Remove wet carpet or other materials

- Extract water

- Remove baseboards and prepare for drying

- Cut and remove wet drywall

- Install containment, if necessary

- Apply necessary chemicals, anti-microbials, etc.

- Setup fans, dehumidifiers, etc. to begin drying process

- Demobilize equipment

The specific order of the tasks can obviously be adjusted for your specific process.

Next, identify the hazards for each task. Some examples would be:

- Mobilize equipment/Move items - Strains and sprains

- Setting up equipment - Trip hazards

- Removing carpet/Removing drywall – Hand pinch and cut hazards

- Cutting drywall – Disturbance of asbestos containing materials

- Chemical application - skin or eye contact

Now you will Identify how to eliminate or minimize each hazard; for instance:

- Strains and sprains – Lift with legs, not back. Use the buddy system or cart/dolly

- Trips – Tape down cords and position alongside walls

- Pinch/Cuts – Wear cut-resistant gloves. Cut away from your body.

- Skin/Eye contact – Follow SDS; wear gloves, safety glasses, etc.

I recommend keeping the tasks relatively simple and broad-scoped. My experience is that most jobs will have 10 or less tasks. Certainly, there are complex jobs that could have more tasks. However, a four-page JHA probably has less chance of being read and followed than a JHA that is more condensed. Additionally, for those complex jobs, don’t be afraid of creating separate JHA’s for different phases of the job – for example, extraction & drying, demolition, and rebuild.

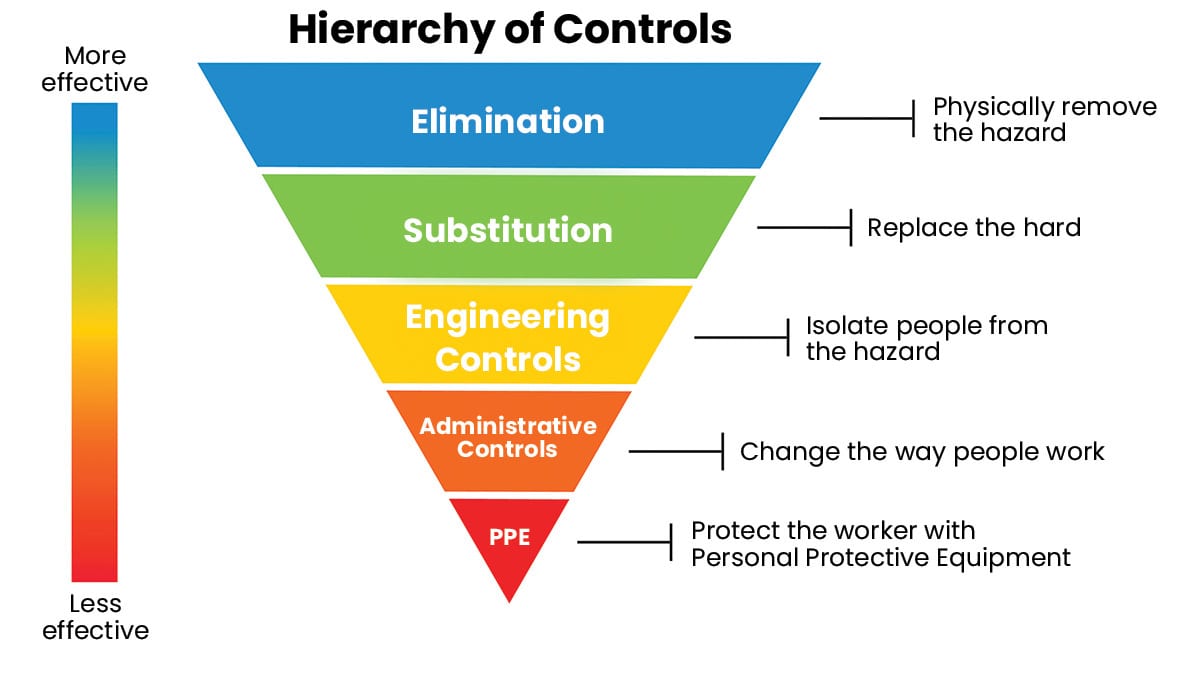

Consider the Hierarchy of Controls as you evaluate your hazards and how you will control them; always try to utilize elimination, substitution, or control of the hazards before putting workers in PPE.

Here is the hierarchy triangle:

Finally, review the JHA with site workers and have them sign it.

Sometimes in the restoration world, we get caught up in the urgency of the situation and lose focus on other aspects of the work. That can result in forgotten tools, having the wrong equipment, and not tracking labor hours or equipment operating hours. Any of those missteps can negatively impact a job. However, forgetting to identify and control hazards can result in employee injuries that not only impact a job, but negatively affect their health, their families, and even the restoration business. As the old saying goes: “An ounce of prevention is worth a pound of cure”. Take 5 or 10 minutes prior to the start of jobs and complete a JHA for your restoration work.

Reference:

- General Duty Clause, Section 5(a)(1) of the Occupational Safety and Health Act of 1970.

- 1910 Subpart I, Appendix B.

- CDC/NIOSH Hierarchy of Controls: https://www.cdc.gov/niosh/topics/hierarchy/default.html

Barry Rice is a Certified Safety Professional (CSP) with over 20 years of experience. He is the Environmental, Health, and Safety (EHS) Director for Signal Restoration Service’s family of companies that includes Signal, PuroClean, and others. Mr. Rice has supported EHS efforts in various industries, including environmental restoration, heavy industrial manufacturing, mechanical field service, automotive and aircraft manufacturing support, residential and commercial construction, and disaster restoration. If you have questions or would like to speak to Barry, he can be reached at 248-878-5662 or barrynrice@gmail.com.